2021

Flow-Liner's CIPP at the Columbus Zoo

The Columbus Zoo and Aquarium is a non-profit zoo located in Delaware County, Ohio. It has a worldwide reputation, largely attributable to the efforts and promotion of director emeritus Jack Hanna. Learn more about Jack and the zoo's history here.

Recently, the zoo discovered air leaking into their water filtration pipes. Excavation to repair these pipes would be very disruptive to the animals, employees, and visitors. Since the zoo has employed the use of Flow-Liner's trenchless technology one or twice before, they knew exactly who to call. In short time, a Flow-Liner Certified Installer arrived to solve the problem. Approximately 250 feet of 4" and 6" water filtration pipes were cleaned in preparation for CIPP (Cured-in-Place-Pipe). The crew was able to successfully navigate many bends along the way and complete the full pipe rehabilitation.

Columbus Zoo Conservation

"Columbus Zoo contributes to saving wildlife through direct participation in and funding of conservation projects, educating visitors and inspiring behavior changes, and modeling our support for conservation through our environmental sustainability practices." By choosing CIPP technology for their infrastructure rehabilitation, they hold true to their stance on environmental sustainability practices. Cured-in-Place-Pipe lining is an eco-friendly alternative to open-cut replacement of existing pipes, ducts, and conduits. It reduces GHG emissions significantly, (on average 80-90%) due to the lack of need for excavation equipment. CIPP has much less noise and air pollution. With little to no above-ground demolition, significantly less dust and debris is stirred up, and the use of loud equipment is minimal.

Utilizing CIPP for Preventative Maintenance

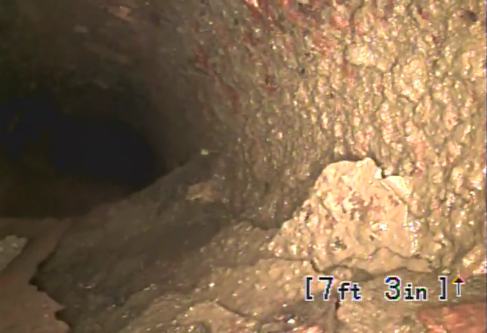

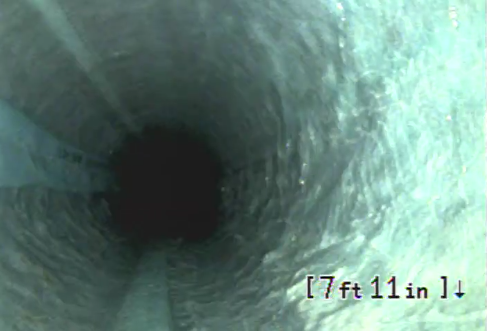

A national testing facility in Michigan decided to get ahead of the game and stop a problem before it started by contacting a Flow-Liner certified installer for Cured-in-Place-Pipe lining. While these pipes had no noticeable sign of issue from the outside, the image (pre-lining) shows that it was only a matter of time before a serious problem arose, as scale was building up inside of the pipes. As you can tell in the post-lining picture that large chunks of scale debris were removed during the cleaning process, providing the smoothest surface possible and most unrestricted flow for the rehabilitated pipe. The lining crew made short work of the job, lining several pipes of varying diameters, and with many of those containing a transition along the way. The customer was delighted with the outcome of the project, particularly with how quickly the job was completed.

Flow-Liner CIPP Utilized at Egg Processing Plant

This Nebraskan Egg Processing Plant was in quite a predicament when one of their unique processing pipes was found to be cracked and with leaking joints. The pipe was under the concrete floor, walls and tons of heavy and expensive equipment. The cost to correct this with a traditional dig-and-replace method was not only expensive, but also inconvenient with the need to move equipment and delay the facility's production. A Flow-Liner certified installer was contacted to make this project less detrimental by using Cured-In-Place-Pipe (CIPP) lining.

While using trenchless methods like CIPP relieved the customer from the headaches of demolition, the project was not without challenges. The cracked and leaking pipe had seven bends to navigate along the way.Along with the numerous bends, there was also a change in diameter halfway through the pipes, adding an extra layer of difficulty to the installation. Despite all of the challenges, our expert installers were able to successfully line the pipes.

Milwaukee Federal Building and US Court House

Milwaukee's Federal Building and U.S. Courthouse was originally an existing 1859 post office that had grown inadequate due to the evolution of postal services. In 1889, it was built up to house the U.S. Postal Service, Courts and Customs Service. More additions were constructed in 1932 and 1940. In 1973, the building was listed in the National Register of Historic Places. A massive seven-year restoration project began in 1989. More recently, in 2019, it was found that the old roof drains were in need of restoration. To preserve the historic building as much as possible, Flow-Liner’s Cured-in-Place trenchless technology was utilized. Most drain pipes are lined top to bottom, allowing gravity to help with the inversion and/or extension of the resin-soaked liner. Lining vertically is much more challenging, especially in longer lengths or with bends along the way or changes in the pipe size. The Flow-Liner certified installer had the experience and know-how to get the project done. Six roof drains were lined with Flow-Liner's CIPP from the basement to the roof, approximately 85 feet each. Each drain had two 90 degree bends near the top with 6" to 4" transitions too. With these added complications, the customer was skeptical. The Flow-Liner Installer was happy to provide the extra details and walk the customer through the procedure to ease their minds until they had the final product in front of them. In just five working days, the six pipes were successfully rehabilitated, saving this historic building from excessive demolition.

Wright-Patterson Air Force Base

The Wright-Patterson AFB is located northeast of Dayton, Ohio, and has a rich aviation heritage. The pioneering work of Orville & Wilbur Wright from 1899 to 1903 enabled them to achieve the first manned, powered flight. After their success at Kitty Hawk, they returned home to Dayton where they perfected their flying skills in early 1900s. The AFB was in need of a trenchless solution when a 4" underground chilled water pipe was found to be broken between two 90 degree fittings. They contacted a Flow-Liner Installer to see if there was a solution that avoided the costly and excessive demolition of the pipe and fittings. The Flow-Liner Installer recognized the challenge in lining through a break in between two fittings and, to ensure a successful project, prepared an in-house "mock up" to test the process. The mock up proved the installation procedure and CIPP product would be a successful fix to their complex issue. After cleaning of the pipes, the Flow-Liner Installers successfully navigated the bends in the pipe, sealing the break and holding the necessary pressure. Quick-Lock seals were used at the pipe ends. See our Flow-Liner Certified Installer's happy customer review below.

"The challenge to line back-to-back 90 degree elbows in the middle of the 140 foot run drove one of your competitors away from the job; we are glad it motivated you to research, prototype and prove you were up to the challenge. I’ll give you the best compliment I can and spread the word about what a great job you did. Please pass on my congratulations and appreciation to your team."

- Mechanical Engineer at Wright-Patterson AFB

Comfort Systems - Cooling Lines

Comfort Systems USA is a leading building and service provider for mechanical, electrical and plumbing building systems. Today, they are composed of more than 35 operating companies in over 140 locations across the United States. A Comfort Systems location found a need for trenchless technology in their cooling lines. A certified Flow-Liner installer was contacted to rehabilitate the pipes.

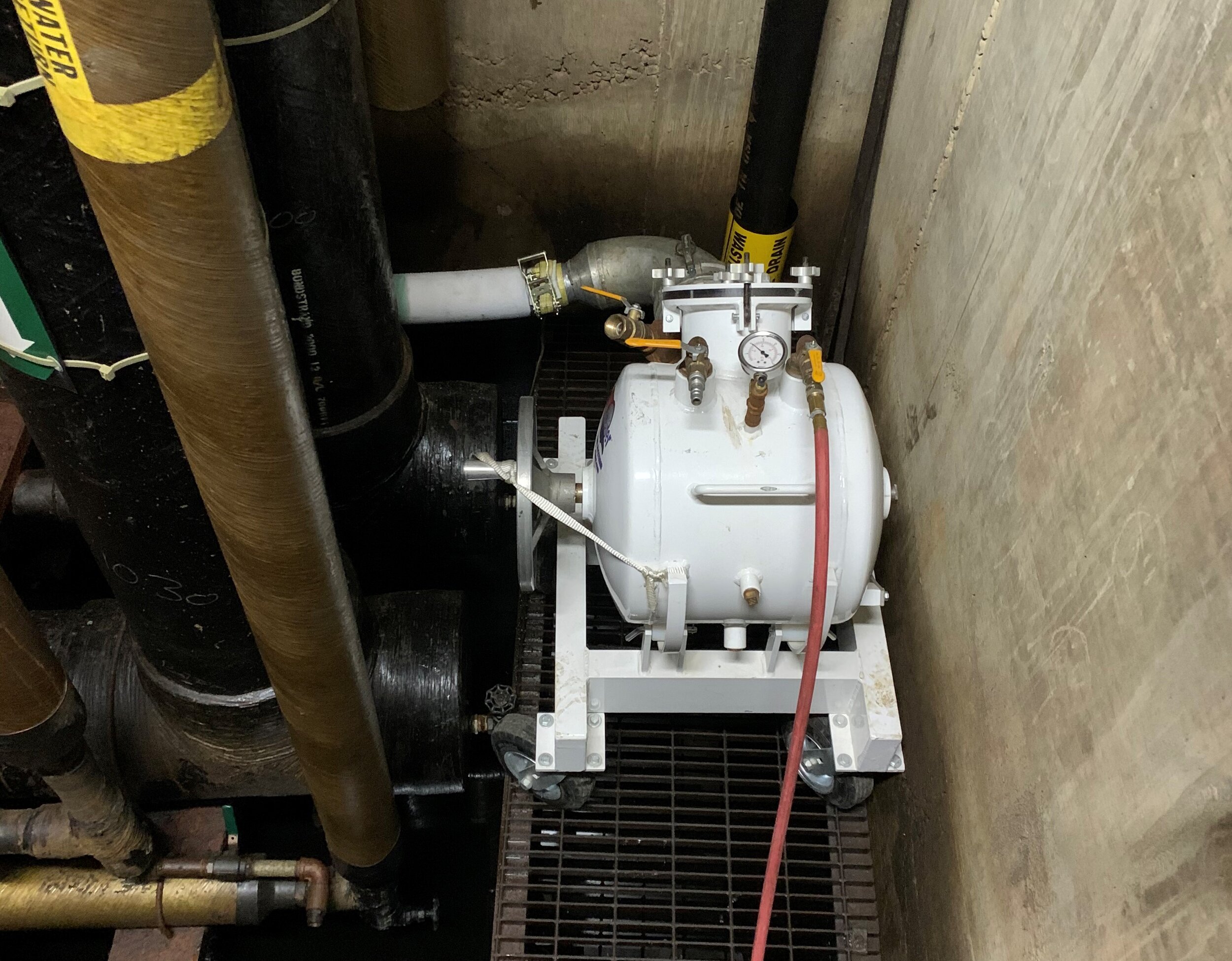

Two pipes were in need of CIPP. Both were voided of all liquids, cleaned, and lined using Flow-Liner's CIPP Inversion, successfully navigating the 90-degree bends inside the pipes. Flow-Liner End Seals were used to ensure a tight seal and protect the CIPP where it enters the pipes. The customer reported their satisfaction with the project, and recommend Flow-Liner's CIPP to others in need of pipe maintenance and repair.