2023

Flow-Liner CIPP at Big Bear Lake Camplands

Big Bear Lake Camplands is nestled in the heart of the Appalachian Mountains of West Virginia. The privately owned family-oriented facility was developed with fun, relaxation, and fellowship in mind. They are committed to a safe, convenient, and affordable camping experience. Since opening in 1972 Big Bear Lake Camplands has brought enjoyment to thousands of happy campers. Set in a lush wooded environment, the camplands offer a back-to-nature atmosphere. Surrounded with over 5000 acres of property to explore and enjoy, Big Bear Lake has become a haven for many outdoor enthusiasts and nature lovers alike. Learn more here: http://www.bigbearwv.com/pageload.cfm

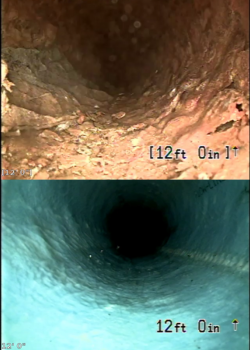

Just in time for the summer rush, Big Bear discovered a leak in their 8" pool pipes. Repairing or replacing this pipe would require the excavation and demolition of the pump room, the water playground, and the concrete around the pool - so they sought out an alternative and found Flow-Liner's Cured-in-Place-Pipe (CIPP) lining.

Navigating Bends: After finding a Flow-Liner installer, Big Bear opted to line 130 feet of pipe to ensure another leak wouldn't inconvenience them again. This required three installations of Flow-Liner's CIPP. The project required the navigation of many bends: two 90s in an 80ft section, four 90s (two of them back to back) in a 16ft section, and one 90 in a 34ft section.

Reinstating Branch Lines: In addition to the challenge of multiple bends throughout the project, one of the installations required lining through a manifold, which then required the use of a robotic reinstatement cutter for opening up 11 branch lines which the Flow-Liner installer navigated with ease. Big Bear was very satisfied that this project only took a few days and didn't interrupt their weekend business.

Fire Main CIPP

A large warehouse for a multinational retail corporation discovered their fire main was leaking. To avoid costly and time-consuming demolition of indoor and outdoor structures, a certified Flow-Liner installer was contacted to provide a trenchless technology solution that would only require a small access pit outside. The Flow-Liner installer started this project with a thorough cleaning of the fire main and then began the Cured-in-Place-Pipe (CIPP) process. The crew successfully navigated a 90-degree bend and lined from inside the building to an access point outside the building, sealing the leak.

CIPP from the Roof down

Active Learners. Innovative Thinkers. Compassionate Leaders. "The Columbus Gifted Academy self-contained program for students in grades 3-8 is located in the Short North areas of Columbus, Ohio. Their purpose is to engage, enrich, and empower gifted learners through unique, rigorous, self-directed educational experiences in a collaborative learning environment that supports the whole child within and beyond the classroom." Learn more here.

During Ohio spring showers, the Columbus Gifted Academy discovered a leak in one of their roof drains. With the desire to avoid costly demolition, they contacted a certified Flow-Liner Installer to explore trenchless methods of repair. Vertical roof drains are no problem for a Flow-Liner crew! The project required Cured-in-place-pipe (CIPP) 25 feet straight down, no demolition needed, and finished in just over a day's time.

"This job went perfect all the way through. Very thorough planning & the plan went 100%. Will absolutely use Flow-Liner again with situations like this."

Gamertsfelder Hall Renovations at OU Campus

Gamertsfelder Hall at Ohio University Campus was built in 1956 and named in honor of Walter S. Gamertsfelder, Ohio University's 13th President. It is a four-story student housing building located in the East Green. For the 2022-2023 year, the building has extensive renovations planned which led one local contractor to contact a Flow-Liner certified installer.

Troublesome Scale Buildup: With an older building, one can expect older pipes. Even if a pipe never cracks or breaks, a buildup of minerals in the water collects on the pipes (called scale) and can lead to serious plumbing issues. During Gamertsfelder Hall's renovation inspections, a worrying amount of scale buildup was found in a drain pipe. This particular pipe also passed under an encased high voltage power feed - making replacement even more of a challenge.

No-Dig, Styrene-free CIPP: So the local contractor searched for an alternative to replacement and found a Flow-Liner Certified Installer. After cleaning the pipe, the Flow-Liner Installer rehabilitated the existing pipe using styrene-free and VOC-free Cured-In-Place-Pipe (CIPP) lining. During the lining process, the crew had to navigate one sharp 90-degree bend and reinstate one branch line. The contractor and renovations manager were both very pleased with the crew's work and avoiding all demolition with no-dig CIPP.

Going Trenchless at Movement on Main

From the moment you step into the Movement on Main dance studio, you'll experience a spacious facility complete with five dance studios, dressing rooms, and waiting rooms with studio viewing windows. The mission at Movement on Main is to inspire students, aiming to grow them both technically and artistically. The instructors and staff accomplish this through progressive, curriculum-based dance classes, and compassionate instruction. Their students will have the opportunity to build character, boost confidence, and expand creativity through the art of dance.

Movement on Main discovered their plumbing issues were stemming from heavy scale build-up and a crack in their drain pipe. From the first floor, to the basement, to just short of the city main line, the pipe in need of repair was 150 feet in length! They contacted a local Flow-Liner Installer for trenchless rehabilitation to avoid the costly and devastating demolition of the studio walls and floors. No need to excavate here! The Flow-Liner Installers were able to install a Cured-in-Place-Pipe (CIPP) in two parts: first, from a toilet flange located on the first floor, then from a cleanout in the basement. This project required the navigation of many bends along the way, and the reinstatement of branch lines with a robotic cutter. The customer was incredibly pleased to entirely avoid all demolition of the beautiful dance studio's floors and walls.