2022

"Excellent group of guys- stayed on task and went above and beyond to make sure all of issues with sewer were addressed and corrected before they completed job. Very professional, polite and explained everything very well. It was pleasure working with them, and we will highly recommend them in the future and would be happy to give excellent reference to anyone needing it." -Maintenance Supervisor of Oriana House

Flow-Liner CIPP at Oriana House

Oriana House began as an independent, non-profit community corrections agency in 1981 with a primary focus of helping the criminal justice system manage driving-while-intoxicated offenders. Today, Oriana House, Inc. is dedicated to helping people triumph over addiction and mental illness and to providing community corrections programming that directs individuals toward developing productive, responsible, law-abiding lives. Their services are available throughout much of Ohio. - Visit Oriana House Website

This Oriana House location discovered a break in their underground drain pipe. Replacement would require a great deal of demolition inside the building, so after searching for an alternative, they discovered Flow-Liner Systems. The Flow-Liner crew found that the break was very close to an access point, but it was decided that they would use Cured-in-Place-Pipe to line the entire length of the pipe to prevent more cracks and breaks in the future. After a thorough cleaning of the pipe, the crew successfully rehabilitated the entire length of the pipe. This job included one diameter transition, five bends, and eighteen branch lines that were reinstated by use of a robotic cutter. The employment of trenchless technology saved the customer from weeks of demolition, downtime, and rebuilding.

Apartment Complex Rehabilitation

A Certified Flow-Liner Installer was contacted by an apartment complex experiencing frequent drain backups. After a televising inspection of the pipe, the crew discovered it was more than just a clog or a root issue, but severe scale buildup. A thorough cleaning job would need to be completed before the installation of cured-in-place-pipe (CIPP).

After cleaning, the crew successfully installed the CIPP through a drain in a bathroom with the compact Flow-40 inversion drum (no digging or demolition needed!), navigating several bends along the way. After the curing process was finished, a robotic cutter was utilized to reinstate branch lines. The customer, and the tenants, were pleased with the timely manner and non-invasive qualities of the project.

Summer Break Rehabilitation Project

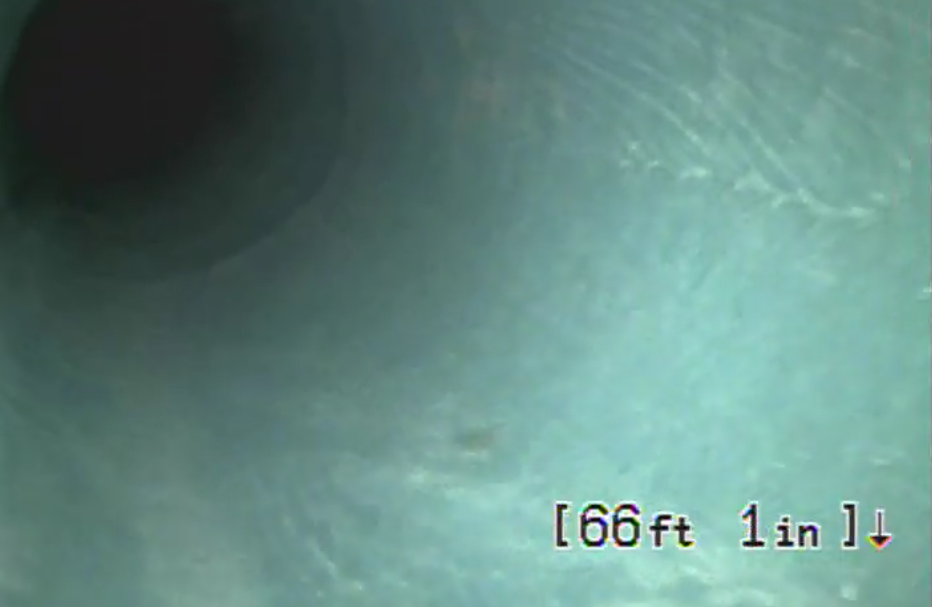

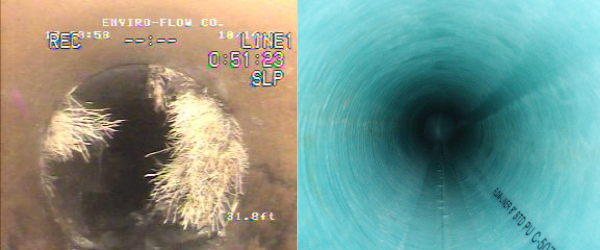

This southeastern Ohio public school took advantage of their summer break and completed a large pipe rehabilitation project using Flow-Liner's Cured-in-Place-Pipe (CIPP) lining. One of CIPP's many benefits is sealing the cracks and breaks that lead to the build up of roots inside of pipes. This was the main issue with the school's drainage system, as seen in the before and after picture below. For a project like this, the Flow-Liner crew completed a very thorough cleaning to remove all of the roots along this 270 feet of pipe, allowing the CIPP liner to pass through. After installation, expansion and curing of the CIPP liner, three branch lines were opened with a robotic cutter, allowing flow to other pipes. Avoiding the excavation of 270 feet of pipe makes for a happy customer!

Historical Lake County Courthouse

The historical Lake County Courthouse contacted a Flow-Liner Certified Installer after discovering issues in two different drains. Both drains were in need of cured-in-place-pipe lining : one was lined vertically, from the basement to the rooftop, approximately 50 feet in length, and the other from an inside cleanout to approximately 35 feet downstream. The Flow-Liner Installer utilized two of Flow-Liner's inversion drums, the small Flow-40 (as pictured) and the next size up, the Flow-120. Both pipes were successfully lined, sealing all leaks and cracks along the way and without disruption of the courthouse operations. "The crew leader was extremely knowledgeable and explained the process of lining the roof drain in our historical building. The entire team listened to my concerns and catered to our needs. They were professional and courteous to all of our staff. The entire process was seamless. The departments we worked in were able to continue to operate without interruption. Overall, the entire experience was amazing. We, as an organization, will look at this process as an option moving forward if any other difficult situation that arises." -Buildings & Grounds Supervisor

Camp Hill United Methodist Church

After ongoing drain clogging and backups, a local contractor reached out to Flow-Liner Systems in order to find an affordable and efficient way to fix the church's issue. The crew televised the 160ft pipe and discovered that the pipe was full of tree roots. After thoroughly cleaning the pipe and cutting out all of the roots, the CIPP lining process could begin. The crew, using the inversion method, installed the resin impregnated CIPP liner into and throughout the pipe, followed by a calibration tube to hold it in place while it cured. The process, start to finish, only took the crew a day and a half of on-site time. Using trenchless technology saved the church from the headache of digging up 160 feet of pipe, saving their landscaping, sidewalks, and structures from demolition and reduced GHG emissions by approximately 80%. "The guys on site were very professional and pleasant to work with. The project manager, Jim, communicated stages of the job very well. The end user, our customer, is very pleased with the way things were handled and the finished product. I will recommend this Flow-Liner Installer to my customers or anyone in need of this service. Thank you!" -Local Contractor Project Manager

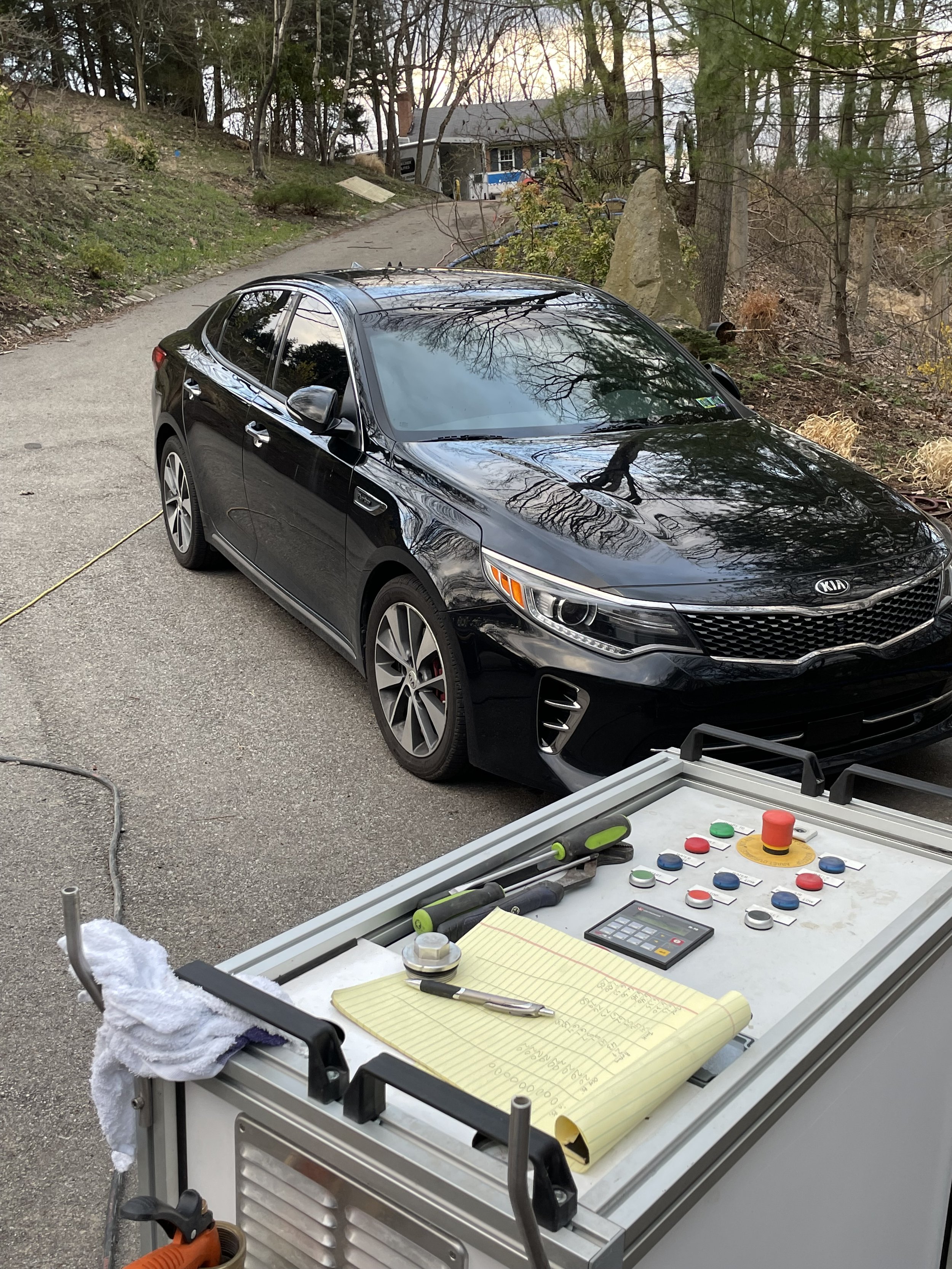

Neofit®+Plus EPP for Leaky Copper Water Pipes

This Pittsburgh residence discovered that their copper service pipe was leaking. The pipe was ~220 feet long, with 25 feet of elevation from the shut off to the in-house connection. Some of the pipe ran alongside and under a paved driveway and wooded area with many trees. With Neofit+Plus EPP, the only digging required was a small access pit at the shut off valve located at the end of the long paved driveway- leaving the driveway, trees, landscaping and other structures untouched. No need to demolish the walls or floors inside either- Neofit+Plus expands to fit your existing pipe and then easily reconnects to the rest of your indoor piping. This residential job used a simple pex crimp fitting to reconnect to the rest of the home's indoor plumbing. Neofit+Plus is not only great for fixing leaking service pipes, it's also an excellent solution for removing toxic lead from your drinking water. The EPP creates an impenetrable barrier between the lead pipes and your water, protecting you, your loved ones, or your customers from toxic lead contaminants.

Conduit Rehab at GEneral motors global tech center

The General Motors Global Technical Center is globally recognized as the preeminent innovation center for automotive engineering, design, and advanced technology. Here, the world’s best designers and engineers come together to help redefine the future of transportation. The 710-acre campus in Southeast Michigan is home to over 21,000 employees. The Tech Center opened in 1956 and is currently recognized as a National Historic Landmark.

A Certified Flow-Liner Installer was contacted to rehabilitate existing conduits at the General Motors Global Technical Center. First, a jetter was used to clean three conduit pipes, one 2" in diameter, two 4" in diameter, and each approximately 200' in length. Next, the CIP-conduit liner was installed, successfully navigating bends along the way. No excavation or demolition necessary for this CIP-Conduit project!

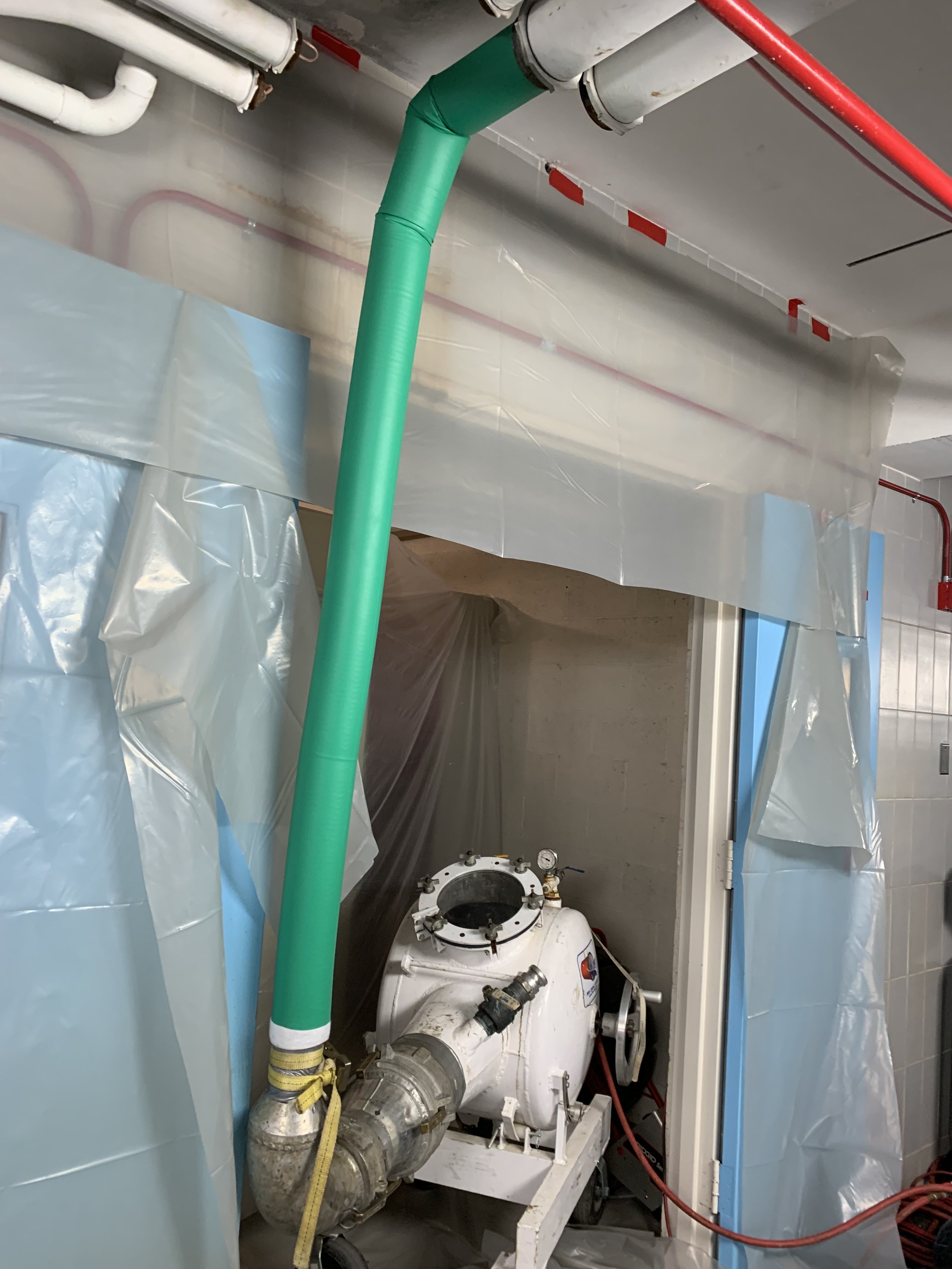

Crisis Averted Thanks to Flow-Liner's CIPP at an Ohio Coca Cola Facility

"The crew did a fabulous job (professional) always keeping us aware of what was going on pertaining to the project. Would highly recommend this crew for any upcoming work with Coca-Cola or any other project for us."

Imagine discovering that the water leak in your manufacturing facility's basement wall is coming from leaking pipes. Imagine those pipes are buried deep under five feet of concrete and under three sets railroad tracks.... Imagine learning that you DON'T have to destroy the concrete and railroad tracks or dig up those buried leaking pipes to fix your problem.

With Cured-in-Place-Pipe lining, avoid costly, time-consuming, high-pollution excavation and demolition that traditional dig-and-replace requires. That's exactly what a local contractor at an Ohio Coca-Cola facility did. A local Certified Flow-Liner Installer was contacted about this project that required reinstating branch lines and the challenge of lining through a P-trap. P-traps include several bends that traps liquid to prevent sewer gases from exiting back through the drains. The experienced Flow-Liner crew successfully lined the leaking pipe inside the facility building, through the P-trap, under the railroad tracks and concrete slab, and reinstated the branch lines with a robotic cutter.

Flow-Liner's CIP-Conduit at Cape Canaveral

Cape Canaveral is located on the east coast of Florida in a region known as Space Coast. The Cape Canaveral Space Force Station and the Kennedy Space Center are both located in this region and are well-known launch sites for many US spacecrafts. A Certified Flow-Liner installer was contacted to utilize CIP-Conduit (Cured-in-Place-Conduit) at Poseidon Wharf East along Port Canaveral.

A contractor local to the Space Coast region discovered several 4" underground conduits in two separate duct banks were showing signs of deterioration. Traditional dig-and-replace would require the costly and inconvenient demolition of the duct banks and a large portion of the wharf itself. With CIP-Conduit, only small access pits were required to remedy this problem. The project entailed the rehabilitation of 12 conduits approximately 60 feet in length each. The local contractor prepared the small access pits and the ducts for the Flow-Liner installation crews. With two installers per crew, six conduits were successfully lined per day, totaling only two days of the Flow-Liner CIP-Conduit installers on site.