2018

Youngsville Borough - Quick-Lock

A Certified Flow-Liner Installer utilized Flow-Liner's newest offered product, Quick-Lock, at the Youngsville Borough. The Borough discovered two abandoned water lines leaking underneath a building. Using the NSF-61 approved Quick-Lock Point Repair Sleeves, both abandoned lines were effectively sealed, eliminating both leaks. With access to the main opened, the installation took only one hour.

"The crew did a great job for us in a timely manner... and saved us from having to dig up and replace the piping." -- Youngsville Borough Foreman

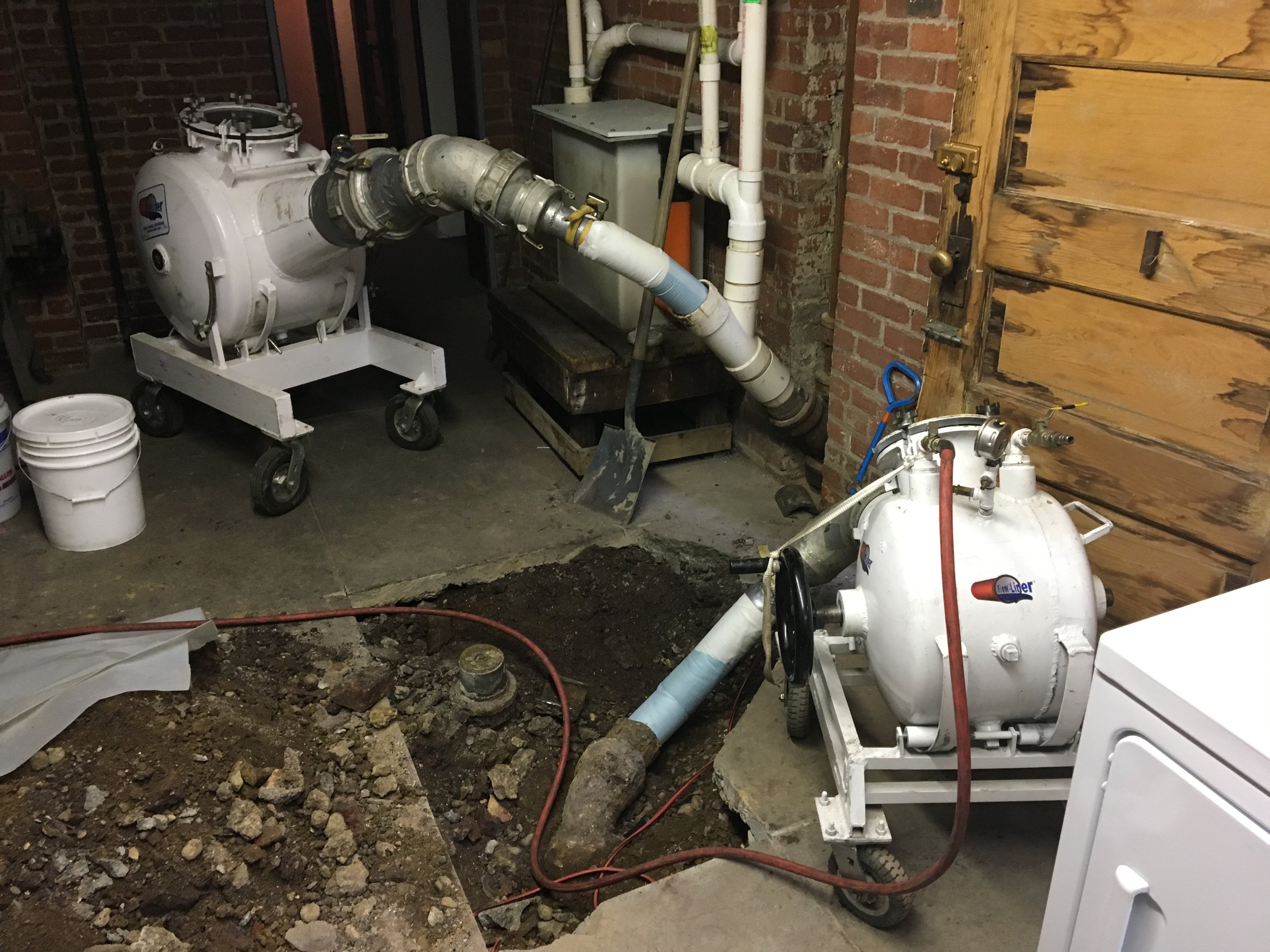

Chattanooga Fire Protection

Chattanooga Fire Protection contacted a Certified Flow-Liner Installer after discovering their customer was in dire need of Cured-in-Place-Pipe (CIPP) lining. In less than a full two day's work, the Certified Flow-Liner Installer, using a specially designed CIPP liner, was able to successfully line the existing fire line, navigating the vertical to horizontal elbow with no issue. Due to Flow-Liner's trenchless CIPP system, the customer did not have to demolish the concrete floor and wall.

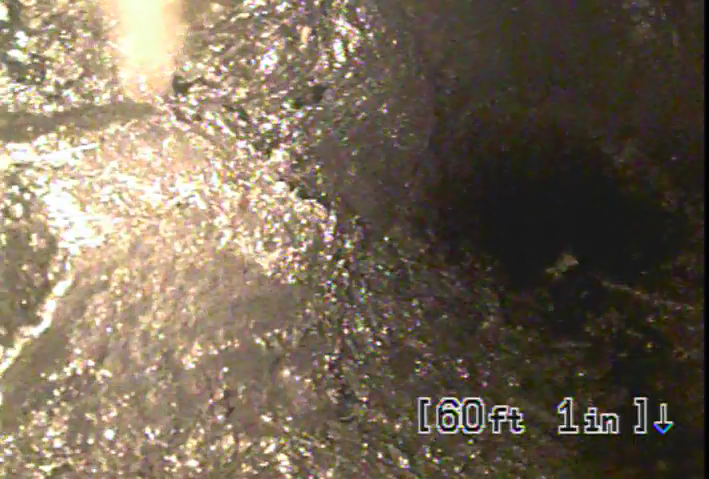

Naval Station Norfolk

Naval Station Norfolk is a United States Navy base in Norfolk, Virginia. It supports naval forces in the United States Fleet Forces Command, those operating in the Atlantic Ocean, Mediterranean Sea, and the Indian Ocean. The installation occupies about 4 miles of waterfront space and 11 miles of pier. It is the world's largest naval station, with the largest concentration of U.S. Navy forces. General Contractor Blackwater Electric discovered the naval station had a need for trenchless technology and contacted a Flow-Liner Certified Installer. The contractor had found issues with stringing the naval station's underground electrical conduit lines and discovered the conduits were too congested to work in. The Certified Flow-Liner Installer performed a thorough cleaning procedure to open up the conduits. After the lines were cleaned and opened back up, approximately 3000 feet of conduits were lined using Flow-Liner's CIP-Conduit® inversion method. Both Blackwater Electric and Naval Station Norfolk were pleased with the use of Flow-Liner's trenchless technology, and happy to save time and money with pipe lining.

The Colony Square Mall

Built in 1981, the Colony Square Mall is located in Muskingum County in Central Ohio. The mall houses over 60 shops, a food court, and various entertainment, such as a 12 screen theater, a putt-putt course, and an arcade. Twenty years after its opening, the Colony Square Mall found a need for trenchless technology. To avoid the high cost and great inconvenience of demolition and excavation, they contacted a local certified Flow-Liner Installer. The installation in 2001 consisted of approximately 600ft of lining, saving the floors and walls of several stores. The Flow-Liner installer used Cured-in-Place-Pipe lining, and successfully lined the underground cast iron drain pipes - with no issues to date! Just this summer, 17 years later, the same Flow-Liner installer returned to the Colony Square Mall. Again, using CIPP, they lined another 250ft of underground cast iron drain pipe, successfully navigating six elbows and reinstating six branch lines.

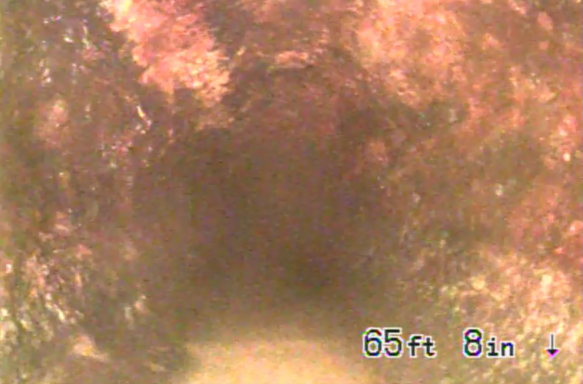

Schultz Mansion

The Schultz Mansion is a well known piece of history in the Central Ohio city of Zanesville, Ohio. Built in the year 1900 for the bride of local businessman, William Schultz, the mansion came with all the trappings of luxury with 26 rooms, seven of them with fireplaces, and a grand ballroom on the third floor with the original, turn-of-the-century Regent piano. Since its original use as a residential property, the mansion has recently been used as an event center in the 21st century. A local contractor discovered the Mansion had existing pipes in need of trenchless technology. A Certified Flow-Liner® Installer was contacted to make the repairs with minimal excavation. After thorough cleaning of the old pipes, the certified installers lined the pipes, including several fittings throughout, with no issue. The contractor was satisfied with the work, "The pipe lining crew was very professional and courteous. They did a great job for us in a timely manner. The pipe lining saved us from having to replace the piping, which would have been very costly and inconvenient."

Detroit Institute of Arts

"The Detroit Institute of Arts museum covers 658,000 square feet that includes more than 100 galleries, a 1,150-seat auditorium, a 380-seat lecture/recital hall, an art reference library, and a state-of-the-art conservation services laboratory. The DIA's collection is among the top six in the United States, with about 66,000 works." The DIA discovered a need for trenchless rehabilitation in their parking garage drain pipes and contacted a Certified Flow-Liner® Installer. Using the CIPP Inversion method, the 50+ year old cast iron pipes were lined successfully without the need for demolition.The customer was so satisfied with the installation that they promised to contact the Certified Flow-Liner® Installer if any more rehabilitation is found to be needed.

Marion City School Systems

Marion City Schools in Ohio found that one of their condenser pipes was in need of repair or replacement. Having already utilized Flow-Liner’s CIPP trenchless technology in a previous project, they reached out to the Flow-Liner Installer again. The Certified Flow-Liner Installer was contracted to in th leaking condenser retur pip s well as install nother IPP iner n the supply pipe for preventative maintenance. Two lines of nearly 400 feet in total were lined using a specially designed Cured-in-Place-Pipe lining via the inversion method. Each line had six bends each, all of which were successfully navigated, lining the pipe in full. Using Flow-Liner’s trenchless pipe lining enabled Marion City Schools to rehabilitate their pipes without the destruction of their driveway, parking lots, and floors. “This is the second project that the Certified Flow-Liner Installer has done for Marion City Schools and we are very pleased and would certainly recommend their services.”

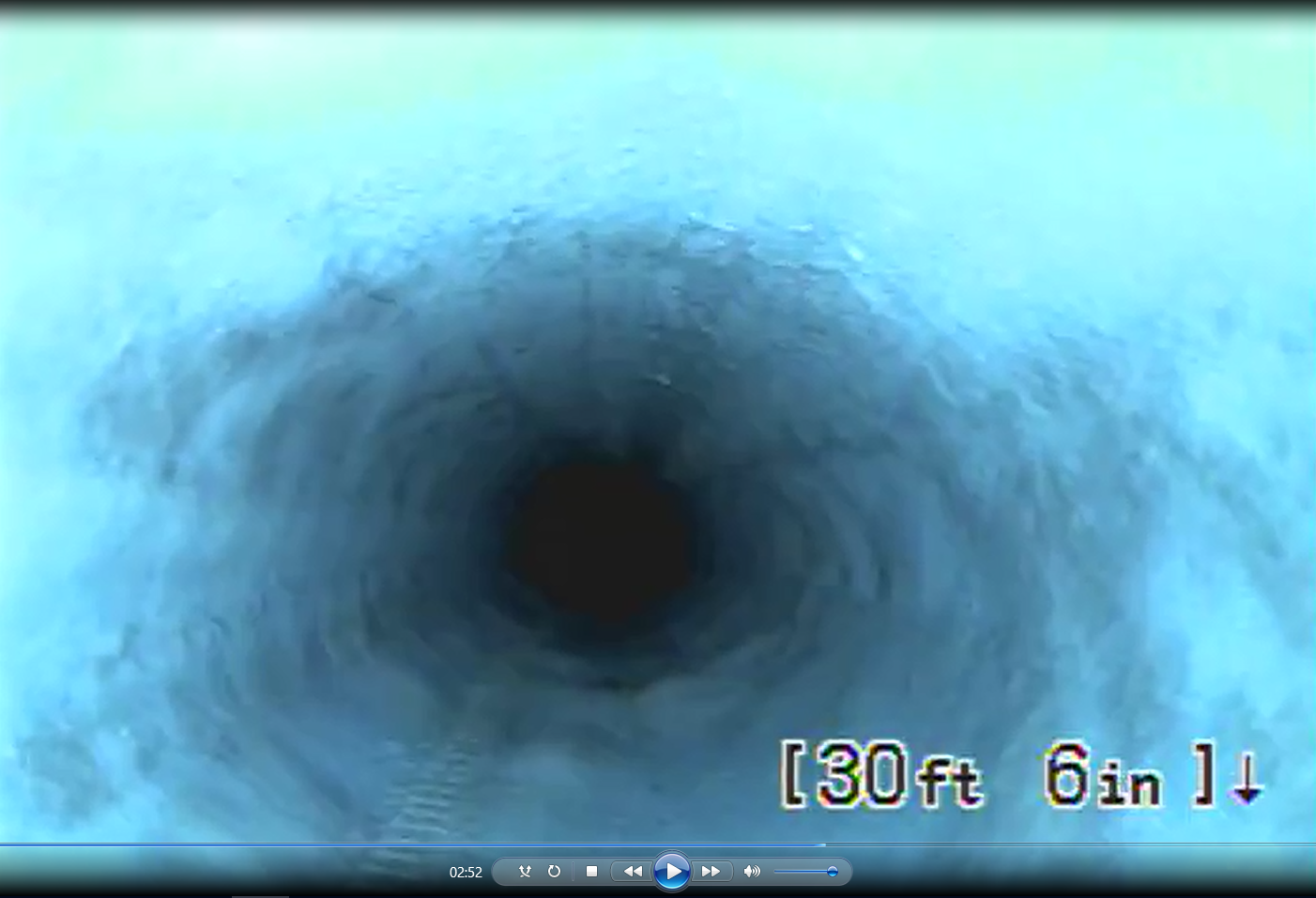

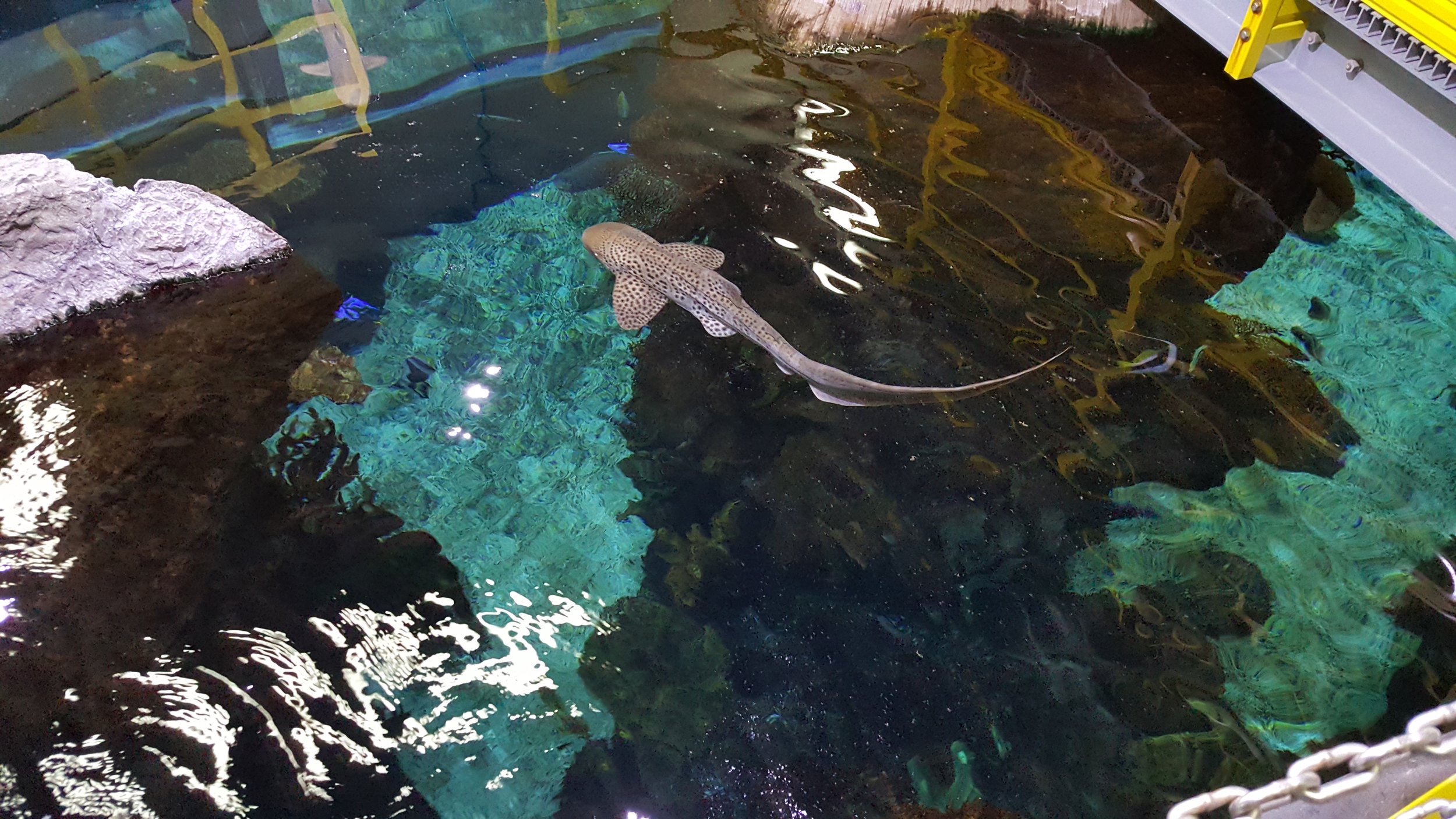

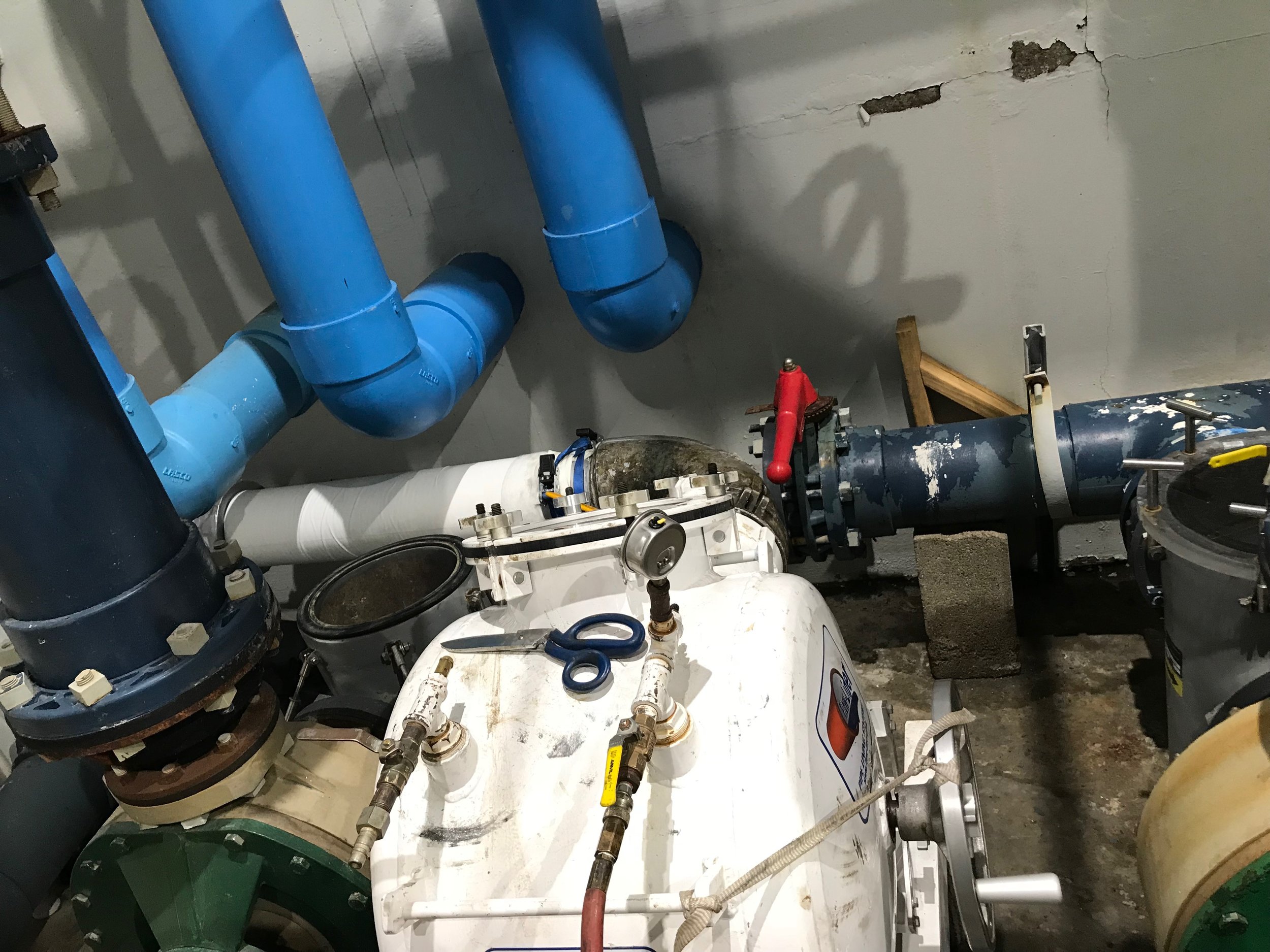

Columbus Zoo & Aquarium

"The Columbus Zoo and Aquarium is a world of adventure that does a world of good. The Zoo is home to more than 9,000 animals representing 650 species from around the globe." The Aquarium's Discovery Reef found that a system pipe was leaking. To avoid the high cost and great inconvenience of replacement, a certified Flow-Liner® installer was contacted to utilize trenchless technology.Flow-Liner's certified installer had to recruit a scuba diver for assistance in the initial televising of the pipe. The Flow-Liner® installer, using the CIPP inversion method, successfully lined the pipe. The project was completed with only eight hours of on-site labor, and finished over the course of 24 hours. "[Flow-Liner] saved us from having to completely replace and reroute the piping. This not only saved us money but also time, very convenient to use this procedure." -- Director of Facilities

Moffat Pipe - New Raleigh Convention Center

The new Raleigh Convention Center (2008), is a 500,000sqft event center complete with 20 meeting rooms, a magnificent ballroom, a large exhibit hall and the beautiful street level mezzanine. Several hundred feet of drain pipes were found to be in need of replacement. The customer was looking for an alternative to traditional dig-&-replace, so their general contractor contacted a certified Flow-Liner® Installer. Utilizing the Flow-Liner® Cured-in-Place-Pipe lining system,11 pipe segments using 20+ liners, varying in diameters 4" to 8", were successfully lined. Several of the segments included bends, and several branch lines were reinstated with the use of a robotic cutter. The general contractor, Moffat Pipe, and the facility employees were amazed at the procedure and further impressed as the crew completed the project ahead of schedule. -"If given the opportunity, our firm would use Flow-Liner® again." --Project Manager of Moffat Pipe, Inc.

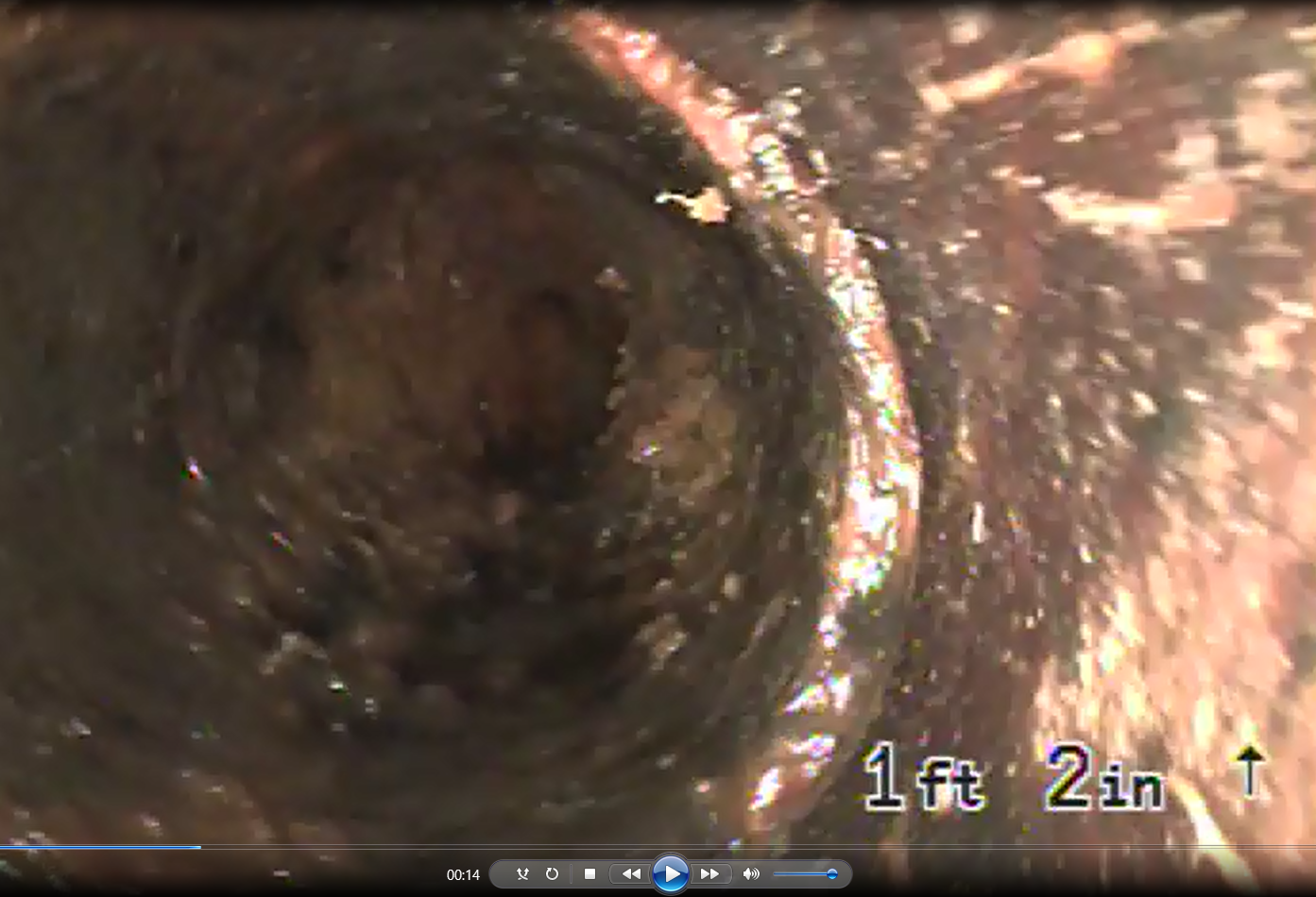

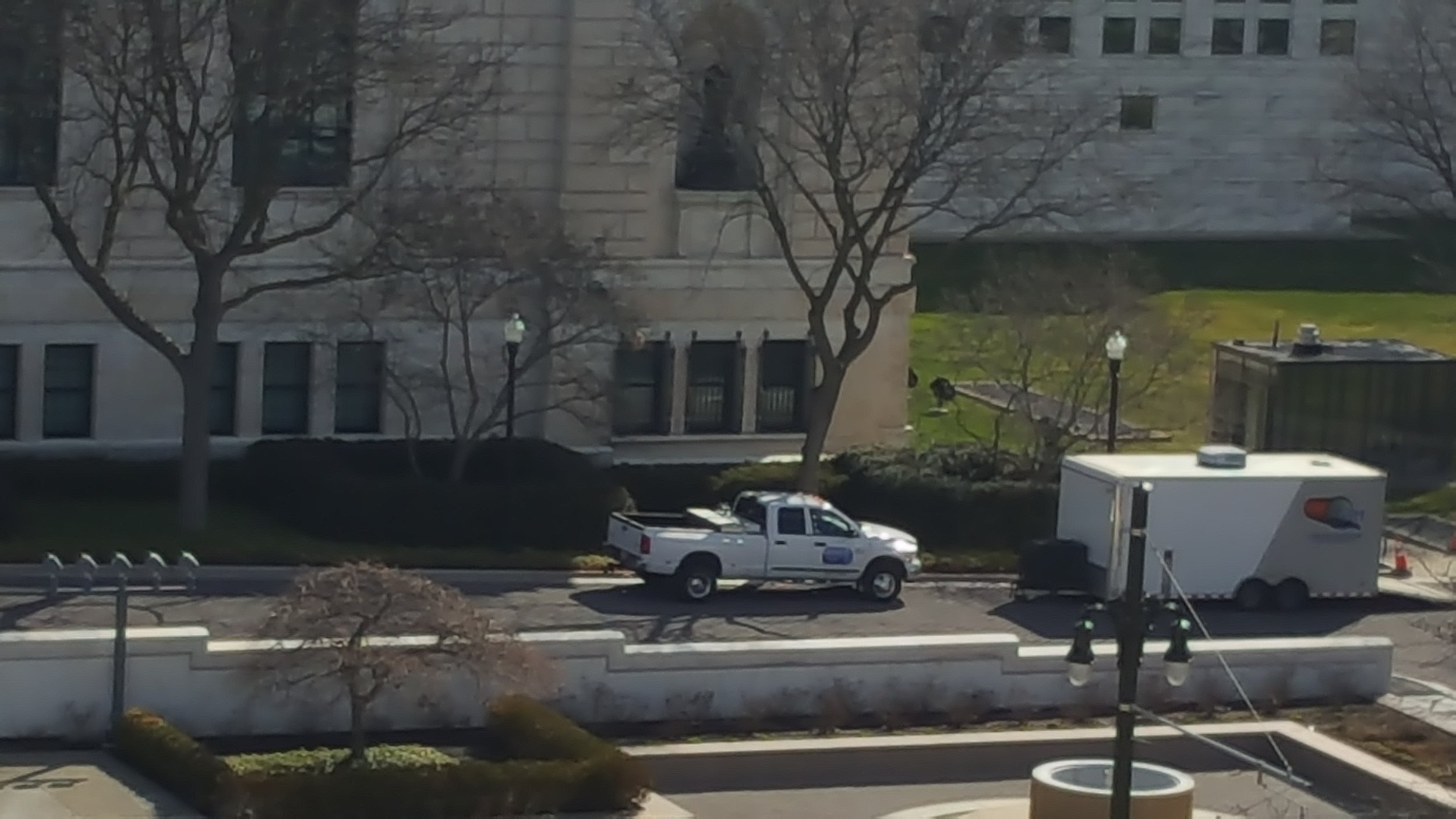

Erie Affiliates - Dayton Federal Courthouse

A Flow-Liner® Certified Installer was contacted by General Contractor Erie Affiliates to implement trenchless technology at the Dayton Federal Courthouse. A leak in the cooling water supply line was discovered. The line ran underneath the parking lot, making this the perfect job for non-invasive trenchless technology. After cleaning the pipe, the Certified Flow-Liner® Installer successfully navigated several bends throughout the pipe and efficiently lined the entirety of the pipe without issue, despite the discovery of a significant belly in the pipe.

"Your crew came on the project and worked professionally and cleaned up after themselves. There was a problem with the existing pipe in that a "belly" in the line caused an excessive amount of water, but the men took care of it without complaint and completed the job in a timely manner." - Erie Affiliates